-

Lengvi odiniai darbo batai MODULO LOW LEATHER S3S

Regular price 112,50 € su PVMRegular pricethe unit price per -

Lengvi neperšlampantys universalūs batai MAMBA O6 HIGH, su itin neslidžiu padu

Regular price 119,00 € su PVMRegular pricethe unit price per -

Neperšlampantys lengvi darbo batai MAMBA O6 MID

Regular price 114,50 € su PVMRegular pricethe unit price per -

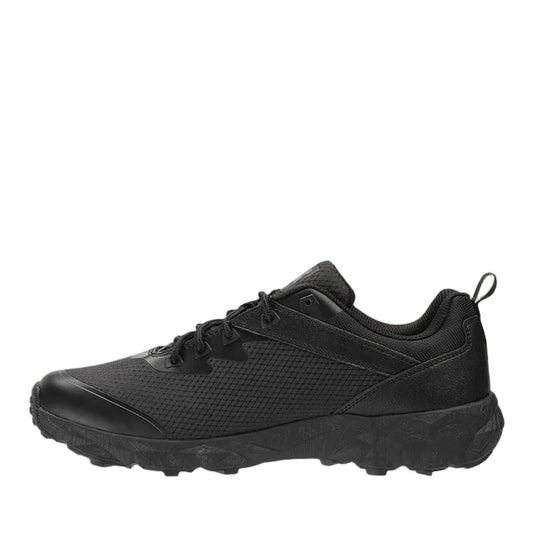

Neperšlampantys lengvi darbo batai MAMBA O6 LOW

Regular price 107,50 € su PVMRegular pricethe unit price per -

itin neslidūs ir orui pralaidūs darbo batai BALTO S1 SR

Regular price 76,90 € su PVMRegular pricethe unit price per -

Odiniai darbo batai HAVEN LOW S3

Regular price 78,50 € su PVMRegular pricethe unit price per -

Stilingi odiniai darbo batai MANAGER S3S, su kompozitine pirštų apsauga

Regular price 82,50 € su PVMRegular pricethe unit price per -

Žemi odiniai darbo batai X1100 S3 LOW FO HRO

Regular price 79,90 € su PVMRegular pricethe unit price per -

Aukštos kokybės darbo batai MODULo PURE S3S, atitinkantys griežtus HACCP higienos reikalavimus

Regular price 94,50 € su PVMRegular pricethe unit price per -

Pilnai odiniai apsauginiai darbo batai su guminiu padu MAYON S3S, rudos spalvos

Regular price 109,90 € su PVMRegular pricethe unit price per -

Pilnai odiniai apsauginiai darbo batai su guminiu padu MAYON S3S, juodos spalvos

Regular price 109,90 € su PVMRegular pricethe unit price per -

Ypatingai patogūs ir kokybiški odiniai darbo batai MODULO MID LEATHER S3S SR HI CI SC ESD FO, rudos spalvos

Regular price 109,90 € su PVMRegular pricethe unit price per -

Darbo batai CATERPILLAR POWERPLANT S3 HRO SRA, rudos spalvos

Regular price 145,90 € su PVMRegular pricethe unit price per -

Žieminiai darbo batai MASCOT S7S, F1104-938, su greito užveržimo BOA Sistema

Regular price 299,90 € su PVMRegular pricethe unit price per -

Winter boots COMPOSITE

Regular price 79,00 € su PVMRegular pricethe unit price per -

Neperšlampantys, apsaugoti nuo smūgių ir pradūrimo darbo batai Safe Hewer S7L

Regular price 107,00 € su PVMRegular pricethe unit price per -

Ypatingai patogūs ir kokybiški odiniai darbo batai MODULO PURE WHITE MID, S3S SR HI CI SC ESD FO

Regular price 89,90 € su PVMRegular pricethe unit price per -

Aukštos apsaugos klasės ypatingai tvirti darbo batai VESUVIO S3 LOW, S3 SRC CI HRO FO

Regular price 89,90 € su PVMRegular pricethe unit price per -

Itin atsparūs darbo batai MASCOT S7S, F1302, su greito užveržimo BOA Sistema

Regular price 284,90 € su PVMRegular pricethe unit price per -

Sportinio stiliaus darbo batai SCALA S1 SR FO HRO, su pirštų apsauga

Regular price 64,90 € su PVMRegular pricethe unit price per -

Žieminiai darbo batai MASCOT S7S, F1107-902-09

Regular price 249,90 € su PVMRegular pricethe unit price per -

Odiniai darbo batai NAMI S1 SR FO HRO

Regular price 64,90 € su PVMRegular pricethe unit price per -

Aukščiausios klasės darbo batai MASCOT S7S, F1300, su raišteliais

Regular price 249,90 € su PVMRegular pricethe unit price per -

Aukščiausios klasės darbo batai MASCOT S7S, F1301, su greito užveržimo BOA Sistema

Regular price 349,90 € su PVMRegular pricethe unit price per